In the race to achieve climate neutrality, solar energy plays an increasingly important role, being the third most used source of renewable energy, after hydro and wind.

In the race to achieve climate neutrality, solar energy plays an increasingly important role, being the third most used source of renewable energy, after hydro and wind.

The use of photovoltaic panels in industry, and more recently, in households, has led to an increase in their number, which, in the medium and long term, will lead to an increase in the amount of electrical waste from them.

Worldwide, the cumulative capacity of installed photovoltaic panels is 942 GW, and this is set to expand as many countries have already started the process of decarbonizing their energy systems. In 2021, the European Union had an installed solar power generation capacity of 162 GW, up from the previous year, and by 2030 EU member states are expected to exceed 750 GW.

The International Renewable Energy Agency (IRENA) has predicted that by 2050, the amount of waste from photovoltaic panels will continue to increase, reaching a value between 60 and 78 million tons, representing 10% of all electrical and electronic waste ( WEEE) produced in that year.

Photovoltaic panels

Composed of aluminum, glass, semiconductors, cables, plastic, copper, silicon but also rare metals, photovoltaic panels have a lifespan of between 20 and 30 years and are considered electrical equipment, which is why their disposal must be done at collection points dedicated to WEEE.

Photovoltaic panels are divided into three generations, depending on the technology and materials used in production: first generation panels, which include monocrystalline, multi- or poly-crystalline modules, being the ones that dominate the market with a percentage share between 80% and 90%, those of the second generation, which include thin-film modules and materials such as cadmium and tellurium or copper, indium, gallium and selenide, and those of the third generation, which are the most technologically advanced, but also least used globally.

A recent study demonstrated that the production of silicon modules from recycled materials has a 58% lower environmental impact than making modules from newly mined materials. Recycling PV panels in the correct recycling streams is all the more important as it is estimated that semiconductor materials, including indium, gallium, selenium and tellurium, will deplete their reserves within 5 to 50 years at the current rate of extraction.

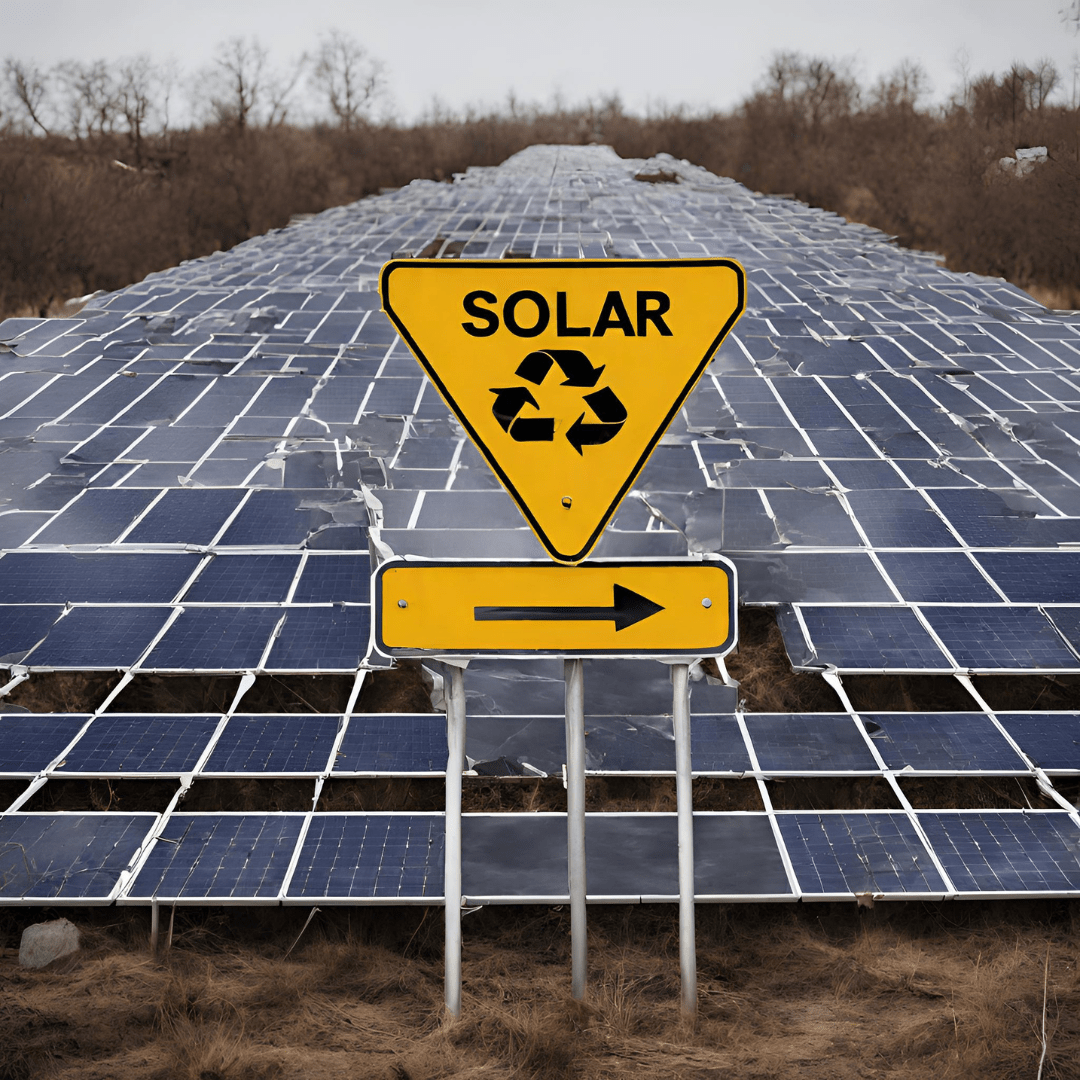

Recycling of photovoltaic panels

The recycling of waste photovoltaic panels is in its infancy, the number of dedicated factories is still small compared to the needs, which is why many of these modules are either recycled together with other types of waste, or incinerated, or disposed of in landfills.

The recycling process of PV panels can be divided into three steps: (i) mechanical, chemical or thermal exfoliation, (ii) chemical stripping and (iii) chemical extraction/refining. However, these phases differ depending on the technology used to make the photovoltaic panels. For example, in the case of second-generation modules containing copper, indium, gallium and selenide, chemical or thermal processes are needed to recover critical raw materials.

At the European level, in order to ensure a quality standard for recycling, the European Committee for Electrotechnical Standardization (CENELEC) developed the EN50625-2-4 standard that describes the requirements from an administrative and technical point of view in the handling of waste from photovoltaic panels.

Overall, the main environmental benefits come from the recovery of aluminum and silicon. Silicon recovered from photovoltaic panels reduces the need to extract and refine raw silicon, thus lowering production costs. In many cases, panel recycling is 78% to nearly 100% efficient in recovering some components.

At present, silicon-based photovoltaic panels are mainly processed in recycling facilities for the treatment of laminated glass, electrical and electronic waste and metals. In these factories, the mechanical approach of crushing and sorting is used to recover some of the materials, such as aluminum, glass, and copper, which are also the main materials on which the extraction and recycling processes are focused.

Another challenge is represented by the existence of critical raw materials, such as gallium or indium, in relatively small proportions in photovoltaic panels, which makes their extraction more difficult. While materials such as aluminum and copper have robust recycling technologies and infrastructure already in place, materials such as indium, tellurium and silicon do not. Against the background of relatively small amounts of waste, the extraction of critical raw materials remains a financially unattractive option.

Good practices

The European Union was the first to adopt regulations on photovoltaic panel waste. EU Directive 2012/19/CE imposes on manufacturers the obligation to finance the collection and recycling costs of photovoltaic panels at the end of their useful life, thus aiming to improve the collection, reuse and recycling of electrical and electronic waste to contribute to the efficient use of resources.

In 2018, a partnership between Veolia and PV Cycle France culminated in the establishment of the first waste recycling plant from photovoltaic panels in France. In 2022, the factory expanded its recycling capacity to 4000 tons of waste photovoltaic panels.

Ramp-PV, a project of France's ROSI SAS, funded by the European Horizon Europe programme, has received the EU's first 'Future Industry Award', in recognition of research and development of low-temperature chemical processes used to recover materials raw materials incorporated in the photovoltaic panels.

The start-up FLAXRES runs industrial-scale recycling operations in a factory in Dresden, Germany, capable of recycling 10 tons of photovoltaic modules per day. He developed a process by which the components of the modules are separated layer by layer using high intensity light pulses at low energy. This patented technology enabled the recovery of silicon, silver and glass.

American company First Solar has set up plants in the United States, Germany and Malaysia and has announced that it can achieve a recovery rate for both cadmium and tellurium between 95 and 97 percent, these rare metals to be reused in First Solar products.

The Romanian context

For more than 3 years, the photovoltaic panel market has gained momentum and is continuously growing in Romania. We see them on houses, on industrial and commercial premises and in photovoltaic farms. More than 20 thousand tons of panels were imported in 2023.

With such a long life, at the time of their end-of-use, the question of financing the costs of collection and recycling will arise. Current legislation requires importers who place such electrical equipment on the market to pay the "green stamp" for such costs. Also in this legislation (which does not distinguish photovoltaic panels from other electrical and electronic equipment) a collection target of 65% is drawn compared to the average of the equipment put on the market in the previous three years.

In conclusion, if quantities of 50 thousand tons were put on the market in the years 2021-2023, about 11 thousand tons of waste electrical and electronic equipment (of course other than photovoltaic panels, not yet out of use) will have to be collected and financed by producers through Responsibility Transfer Organizations.

The solution would be for these equipment to have a target calculated at the level of WEEE generated, and the green stamp given by the importers to be placed in a fund dedicated to the recycling of these equipment.

conclusions

In order to fix the existing challenges and improve the PV panel recycling market, the participation of all stakeholders is important: PV panel manufacturers, waste management companies, research institutes, as well as authorities and the public. The participation of the relevant actors can ensure not only the increase in the amount of waste, which will lead to boosting the recovery of critical raw materials, but also the research and development of treatment, extraction and recycling lines, the establishment of dedicated factories to ensure that the resulting raw materials have a high degree of purity.

At the same time, it is important that manufacturers implement the concept of design for recycling, in order to ensure easy recycling of waste photovoltaic panels. A recycling-friendly design makes it easy to disassemble or separate the various components in the modules, improving the recovery rate and purity of secondary raw materials.

Authors: Diana Trifu and Dragoș Călugăru, ECOTIC General Manager